Supply 55 Guardian Calender - Dye Sublimation Paper Transfer Direct-To-Fabric Thermo Fixation

Supply 55 Guardian Calender - Dye Sublimation Paper Transfer Direct-To-Fabric Thermo Fixation

| Brand: | Supply 55 |

| Product Code: | |

| Availability: | In Stock |

-

$0.00

Supply 55 Click Here

For additional product information Click Here

For video Click Here

For video Click Here

For additional product information Click Here

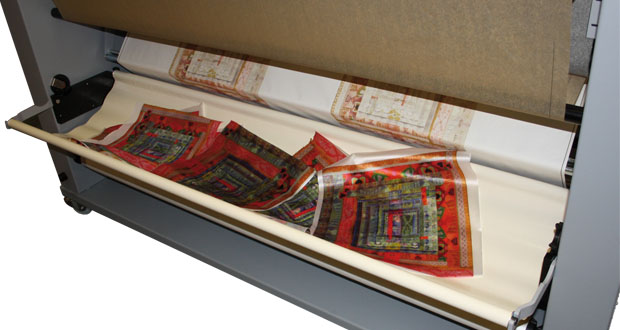

Guardian Calenders are an affordable, easy to use solution for all your dye sublimation paper transfer and direct-to-fabric applications. The Guardian calender’s intuitive design makes for quick and easy use, maintenance and cleaning, thus saving time on production. Solid, all steel construction provides high quality performance and ensures Guardian Calenders are built to last.

Features

• All steel component construction

• Low electrical consumption of 6000w

• Temperature accuracy controlled by a precision Infra-red sensor ensuring consistency during the entire transfer process

• Heat is supplied by a specially engineered Infra-red lamp providing even temperatures when running pieces or roll-to-roll

• Fast warm-up and cool down times save energy and labor

• Nomex felt belt with a Kevlar reinforced center for added durability

• Mechanically adjusted belt without compressed air; the belt does not need adjustment before, during or after the transfer process

Temperature Control

• Temperature is adjustable up to 220°C (428°F)

• Exposure Time: Can be adjusted from 25 to 180 seconds

Control Panel

• Temperature selection and control.

• Selection of exposure time and speed.

• Forward, Stop, Reverse

• Safety reset.

Safety Features

• Guardian Calenders include safety features engineered to provide a safe working environment for the operator:

• Plexiglass Front Cover: Protects the user from the feed mechanism and the risk of burns; also protects the felt belt and drive system from being damaged by foreign objects.

• Emergency Stop Buttons: Two (2) emergency stop buttons are located in the front and rear of the calender.

• System Override: If any of the safety features are activated, the user must press the reset button to reengage the calender.

• Thermo Isolation: All exposed surfaces have been thermo isolated to protect the user from the risk of burns while operating the calender.

Guardian Calender Production Table and Receptacle for Pre-cut Pieces

Tensioning of paper

• Paper Tension is adjustable with the tension adjustment knob located on the table paper feed mandrel (Fig. C)

Benefits of the production table

• The table is removable, allowing for roll-to-roll or piece production.

• Ideal for the production of sportswear and garments using stretchable or non-stretchable fabric.

• Works with tacky or non-tacky paper.

Feeding paper and pre-cut pieces

• Transfer paper can be loaded and tensioned on the front of the table using the transfer paper feed mandrel. (Fig. A)

• The roll feeding guide assists in feeding paper flat into the calenar (Fig. B)

• Printed paper is kept in contact with pre-cut pieces by the pressure bar.

Connecting the table to the calender

• The table is designed to quickly attach and detach from the calender, allowing the operator to seamlessly switch between roll-to-roll and piece production. (Fig. D)

Receptacle for pre-cut pieces

• Easily attaches and detaches to the back of the calender for receiving cut pieces after the sublimation process is complete.

• When not in use, the receptacle can be folded for storage. (Fig. E)

Specifications

Maximum working width: 67’’ (1680 mm)

Maximum temperature: 428°F (220°C)

Diameter of the heating cylinder: 10“ (250 mm)

Heating system: Infra-red

Heating time from room temperature at 200°C: 30 min.

Digital display of temperature: Yes

Driving belt material: Nomex© reinforced by Kevlar for added durability

Speed Exposure time 40 seconds: 71 yd / hr - 1.18 yd / min (65 m / hr - 1.08 m / min)

Speed Exposure time 90 seconds: 18 yd / hr - 0.30 yd / min (17 m / hr - 0.29 m / min)

Reverse operation: Yes

User protection: Safety cover in front of the rollers with safety switches and reset button on the control panel

Exhaust fume extraction: 2?extraction pipes diameter 2” (50mm) linked to both ends of the machine to vacuum smoke and vapors produced during sublimation

Number of self locking mandrels included: 6 universal mandrels, 3 feed, 3 take-up

Maximum material feed roll dimension: Upper position 10” (250 mm) Mid front position 10” (250 mm) Low front position 10” (250 mm)

Maximum Roll Weight: 66 Lbs. (30kg.)

Power: 6000 W

Power Adaptor: Plug L6-30P, Receptacle L6-30R

Voltage: 208V / 50Hz - 60Hz Single Phase

Amperes: Max.?28 Amperes

Dimension of the machine: W 81” x D 38” x H 61” / W?208 x D 96 x H 155 cm

Weight of the Machine: 1060 Lbs (480 kg)

Dimension of the shipping crate: W?86” x D?37” x H 66” / W 218?x D?93 x H?170?cm

Shipping Weight: 1322 Lbs (600 kg)

CE Approved / RoHS Compliant: Yes

Warranty: One year parts warranty