Supply 55 UV Printing Adhesion Promoters

Supply 55 UV Printing Adhesion Promoters

| Brand: | Supply 55 |

| Product Code: | 2807 |

| Availability: | In Stock |

-

$551.99

For additional product information Click Here

For additional product information Click Here

AP2155™ Adhesion Promoter / Anti-static / Cleaner for Plastic Substrates

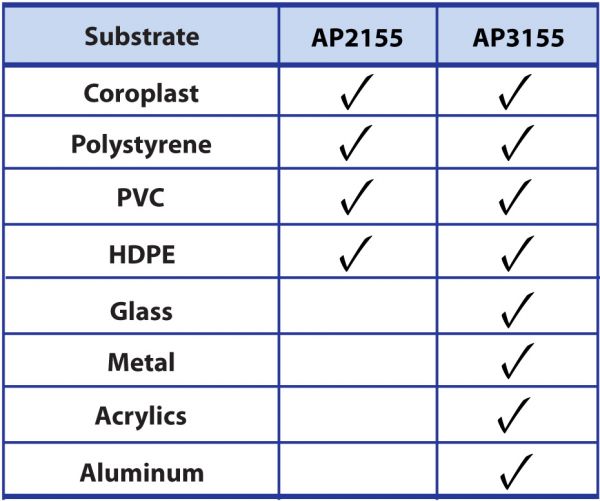

AP2155 is an adhesion promoter, anti-static and cleaner for use with UV and LED curable inks when printing on plastic substrates; Coroplast, Polystyrene, PVC and HDPE.

AP2155 also eliminates finger prints from the printed surface area.

Application Instructions for UV and LED Curable Inks:

1.Wear protective gear including Latex or Nitrile gloves and safety glasses

2.Use in a well ventilated area

3.Transfer AP2155 to a spray bottle

4.Spray AP2155 onto the substrate and wipe off with a white lint free wipe or microfiber cloth (the substrate will feel slippery)

5.Load the AP2155 prepared substrate into the printer and print image using UV or LED curable ink

Part Number:

UV-AP2155L: One (1) Liter Bottle

UV-AP2155G: One (1) Gallon Bottle

Shelf Life: Two (2) years from date of manufacture

AP3155™ Adhesion Promoter for Hard to Print Substrates

AP3155 is an adhesion promoter for use with UV and LED curable inks when printing on Glass, Metal, Aluminum, Acrylics, HDPM, Coroplast, Polystyrene and other hard to print substrates.

AP3155 is suitable for both interior and exterior applications.

Application Instructions for UV and LED Curable Inks:

1.Wear protective gear including Latex or Nitrile gloves and safety glasses

2.Use in a well ventilated area

3.Apply AP3155 to the substrate with a clean, white, lint free wipe or microfiber cloth saturated with the promoter, covering the full surface and insuring no voids

4.Using a clean, dry, white, lint free wipe or microfiber cloth, wipe off AP3155, leaving a thin layer of promoter on the substrate (the substrate will feel slippery)

5.Load the AP3155 prepared substrate into the printer and print image using UV or LED curable ink

6.AP3155 will cure with the ink when flashed by the UV or LED lamp

Paint Gun Application for UV Curable Inks:

1.Wear protective gear including Latex or Nitrile gloves and safety glasses

2.Cut AP3155 with Acetone at a ratio of 50/50

3.Spray a thin even layer of AP3155 onto the substrate using a spray gun outfitted with a fine tip nozzle

4.Load the AP3155 prepared substrate into printer and print image using UV curable ink

5.AP3155 will cure with the ink when flashed by the UV lamp

Glass Special Instructions

1.When printing on glass only print on the float or tin side of the glass

2.To confirm the float or tin side, Illuminate the glass with a black light; the float or tin side of the glass will glow

Part Number

UV-AP3155L: One (1) Liter Bottle

UV-AP3155G: One (1) Gallon Bottle

Shelf Life: One (1) year from date of manufacture